Maligayang pagdating sa aming mga website!

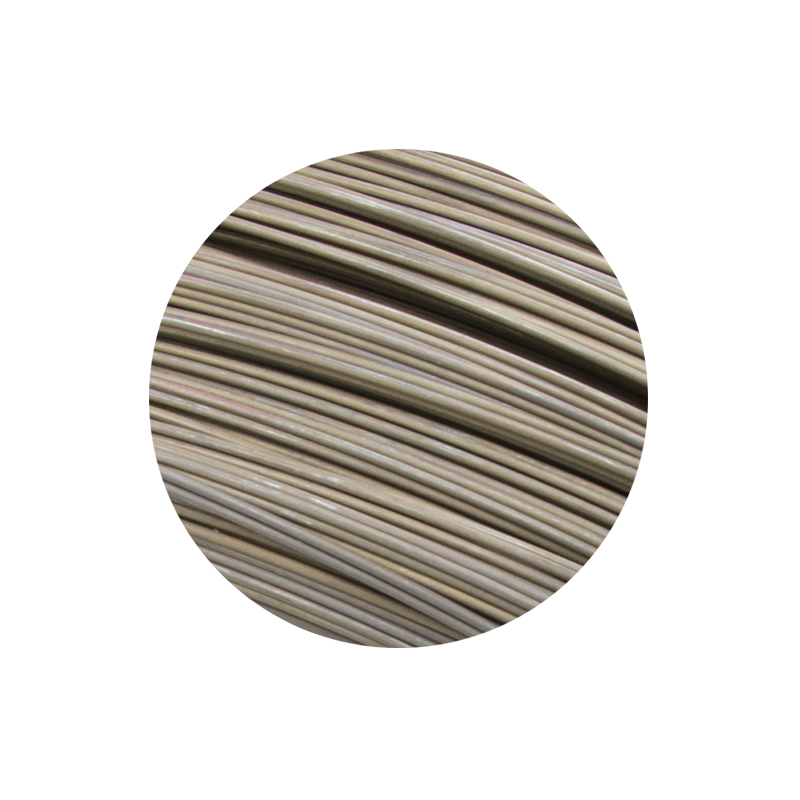

Heat Resistance Electric Wire SWG 20-32 Soft Annealing Bright FeCrAl 1Cr13Al4 Fecral Resistance Heating Wire

Heat Resistant Electric Wire SWG 20-32 Soft Annealing Bright FeCrAl1Cr13Al4Fecral Resistance Heating Wire

Mga Tampok:

- Fecral electrictrical resistance heating alloys na may mataas na electrical resistivity, maliit ang temperature coefficient of resistance. – Magandang corrosion resistance sa ilalim ng mataas na temperatura, at partikular na angkop para sa paggamit sa isang gas na naglalaman ng sulfur at sulfide, mababang presyo. – Ang electric resistance heating wire ay isang uri ng normal na materyal ng fecral alloy.

Mga Application:

- Ito ay malawakang ginagamit sa industriyal na pugon, mga gamit sa bahay, industriyang pugon, metalurhiya, makinarya, sasakyang panghimpapawid, sasakyan,

militar at iba pang mga industriya na gumagawa ng mga elemento ng pag-init at mga elemento ng paglaban.

militar at iba pang mga industriya na gumagawa ng mga elemento ng pag-init at mga elemento ng paglaban.

Saklaw ng Sukat ng Dimensyon:

- Kawad: 0.01-10 mm

- Ribbon: 0.05*0.2-2.0*6.0 mm

- Strip: 0.05*5.0-5.0*250 mm

- Bar: 10-50 mm

- Ribbon: 0.05*0.2-2.0*6.0 mm

- Strip: 0.05*5.0-5.0*250 mm

- Bar: 10-50 mm

| Uri ng Alloy / Pagganap | 0Cr25Al5 | 0Cr21Al6 | 0Cr23Al5 | 0Cr21Al4 | 0Cr21Al6Nb | 0Cr27Al7Mo2 | ||

| Komposisyon | Cr | 12.0-15.0 | 23.0-26.0 | 19.0-22.0 | 20.5-23.5 | 18.0-21.0 | 21.0-23.0 | 26.5-27.8 |

| Al | 4.0-6.0 | 4.5-6.5 | 5.0-7.0 | 4.2-5.3 | 3.0-4.2 | 5.0-7.0 | 6.0-7.0 | |

| Re | Opportunity | |||||||

| Fe | Pahinga | |||||||

| Nb0.5 | Mo1.8-2.2 | |||||||

| Max. tuloy-tuloy na temp ng serbisyo. ng elemento(℃) | 950 | 1250 | 1250 | 1250 | 1100 | 1350 | 1400 | |

| Resistivity sa 20℃(μm.m) | 1.25 | 1.42 | 1.42 | 1.35 | 1.23 | 1.45 | 1.53 | |

| Densidad(g/cm3) | 7.4 | 7.1 | 7.16 | 7.25 | 7.35 | 7.1 | 7.1 | |

| Thermal conductivity(KJ/mh ℃) | 52.7 | 46.1 | 63.2 | 60.2 | 46.9 | 46.1 | – | |

| Coefficient ng pagpapalawak ng mga linya (ax10-6/℃) | 15.4 | 16 | 14.7 | 15 | 13.5 | 16 | 16 | |

| Tinatayang punto ng pagkatunaw.(℃) | 1450 | 1500 | 1500 | 1500 | 1500 | 1510 | 1520 | |

| Katigasan(HB) | 200-260 | 200-260 | 200-260 | 200-260 | 200-260 | 200-260 | 200-260 | |

| Pagpahaba sa pagkalagot(%) | >16 | >12 | >12 | >12 | >12 | >12 | >10 | |

| Ulitin ang dalas ng Bending(F/R) | >5 | >5 | >5 | >5 | >5 | >5 | >5 | |

| Tuloy-tuloy na oras ng serbisyo(Oras/℃) | – | ≥80/1300 | ≥80/1300 | ≥80/1300 | ≥80/1250 | ≥80/1350 | ≥80/1350 | |

| Lakas ng makunat(N/mm2) | 580-680 | 630-780 | 630-780 | 630-780 | 600-700 | 650-800 | 650-800 | |

| Pagkakaiba-iba ng lugar(%) | 65-75 | 60-75 | 60-75 | 60-75 | 60-75 | 60-75 | 60-75 | |

| Mikrograpikong Istraktura | Ferrite | Ferrite | Ferrite | Ferrite | Ferrite | Ferrite | Ferrite | |

| Magnetic na Katangian | Magnetic | Magnetic | Magnetic | Magnetic | Magnetic | Magnetic | Magnetic | |

Isulat ang iyong mensahe dito at ipadala ito sa amin

Mga kategorya ng produkto

-

Telepono

-

E-mail

-

Whatsapp

-

WeChat

Judy

150 0000 2421

-

tuktok